Products Center

Technology, Integrity, Efficiency, Quality, Innovation, Development, Service

About Us

Dalian mqing machinery and electronic co.,ltd.

With current registered capital of 10 million and the plant area of 3,000㎡, Dalian Mingqing Electromechanical Corporation was established in Dalian Economy and Technology Development Area on May 29th of 2006, which is in stable development and increasing power in fierce market competition based on humanized management. delicate processing and fearless innnovation; it’s developed into the intelligence group combined with design, processing, assembly and debugging from the initial small plant of more than 10 people; it currently owns branch companies of Qingdao Mingqing, Suzhou Mingqing,Shenzhen Mingqing and Chengdu Mingqing.

Industry experience

Plant area

Registered capital

Enterprise advantages

Strong production strength

It was established in Dalian Development Area on May 29, 2006, with a registered capital of 20 million yuan and a plant area of 3000 ㎡. With humanized management, fine processing and bold innovation, it has developed steadily and become increasingly powerful in the fierce market competition. From the initial small factory with more than a dozen people, it has developed into an intelligent group integrating design, processing, assembly and commissioning. The existing group branches are Qingdao Mingqing, Suzhou Mingqing, Shenzhen Mingqing Chengdu Mingqing.

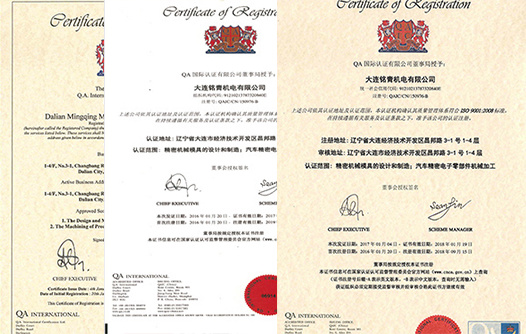

Reliable product quality

Faced with the rapid development of the global economy, the company adheres to the principles of technology, integrity, efficiency, quality, innovation, development, and service, and will definitely bring its products and services to the whole country and the world, completing another leap!

News Center

Technology, Integrity, Efficiency, Quality, Innovation, Development, Service

What equipment and technologies are required for automation of injection molding of embedded parts?

2020-08-27

With the popularization of artificial intelligence and Industry 4.0, automated production has become a trend in the development of the manufacturing industry. The automated production line for injection molding of embedded parts is an efficient, energy-saving, and intelligent production method, which has the advantages of reducing production costs, improving production efficiency and quality. This article will introduce what equipment and technologies are required for automation of injection molding for embedded parts.

Characteristics of vertical injection molding machines

2020-08-27

The automation of vertical injection molding machines not only occupies a small area on the ground, but also has high efficiency, which is more conducive to high-precision molding.

Design, manufacturing, and component processing of precision stamping molds

2020-08-27

Different positioning methods have different influencing factors. When the automatic assembly line process, such as mechanical equipment block positioning, the positioning accuracy is related to the Bending stiffness of the block and the speed when the block is touched.

合作伙伴

技术,诚信 效率,品质,创新,发展,服务

Mozilla

Oracle

Microsoft

Apple

IBM

IBM

IBM

IBM

IBM

IBM

IBM